Solid Punch Rivetting

Joining with solid punch rivets

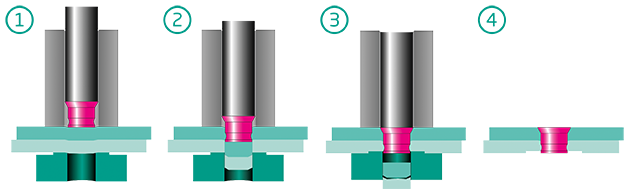

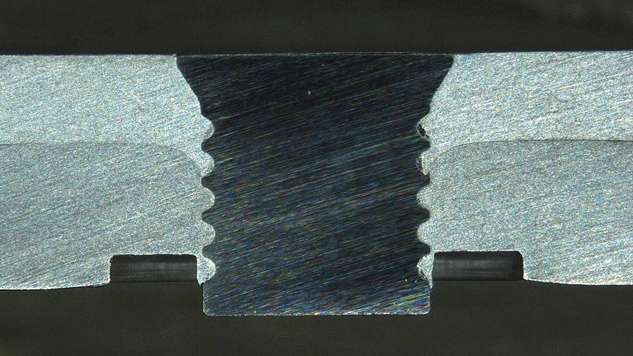

The punch is pushing the rivet through the sheet metal layers, until the rivet is flush with the surface of the punch-side of the part. During the subsequent reprints, the punch and stripper presses the materials onto the embossing ring of the die. The die side material flows into the annular groove of the rivet and a form-lock and force-fit connection is created.

Fixing

Application of rivet

Deformation of rivet and joined parts

Return stroke

With the innovative technology for solid punch rivetting, TOX® PRESSOTECHNIK, the specialists for sheet metal joining, amends their delivery and performance program with a most promising process.

The Solid Punch Rivetting offers an additional mechanic sheet metal joining which is of great importance for lightweight constructions and/or the joining of hybrid parts and subassemblies.

The rivet feeders, the tongs and the tool holding fixtures are of such an universal construction that with the hand-held tongs and the robot tongs it is possible to process solid punch rivets of diam. 4,0 mm and lengths from 3.3 to 8.1 mm, as well as solid punch rivets of diam. 5.0 mm and lengths from 3.9 to 9.0 mm in a flexible way.

For more information about TOX® solid punch joining, please contact us today!

Contact MY: +60 3 80231448 Contact form |

Cookie Information We use cookies to give you the best possible experience when using our website. You can block or regulate the use of cookies by adjusting your browser settings accordingly. |